Awareness. Willpower. Action.

THE EARTH’S DESTINY IS OUR DESTINY. IF WE NEGLECT IT, WE NEGLECT THE QUALITY OF OUR OWN LIVES AND THE LIVES OF GENERATIONS TO COME.

NEOCLEUS

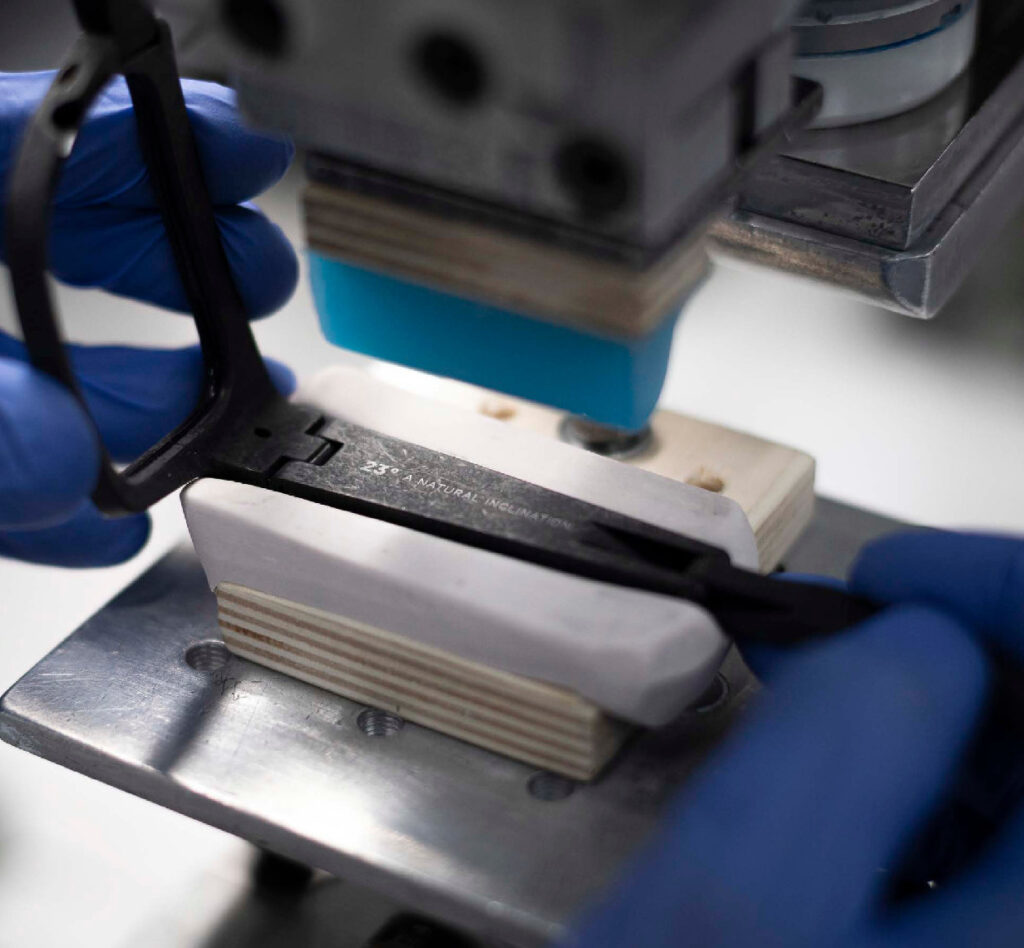

THE ZERO-WASTE IN-HOUSE PRODUCTION PROCESS

SUSTAINABLE PRODUCTION

23° Eyewear is committed to responsible production through the use of:

- BIO BTR 600: an ecological castor plant-based resin produced with bio-mass energy which is renewable and classified as CO2 neutral.

- Mazzucchelli M49 cellulose acetate: a bioplastic composed mainly of material derived from renewable sources.

RESOURCE EFFICIENCY

We reduce our production impact on the environment with:

- Solar panels system for self-producing energy

- Heating pumps for AC and heating

- Inverter compressor air system

- Electric injection equipment which uses 98.7% less crude oil than in dynamic systems

- Tumbling process with contiguous water

- 100% LED lighting

- Electric transport vehicles

- No plastic waste in-house as discarded material is either recycled or upcycled

FRAMES

In harmony with 23° Eyewear’s circular “eco concept”, all frame components are conceived and intended to be recycled or upcycled. The frame hinges, designed and engineered with a removable optical stainless-steel screw, to be easily recycled, are solid but lightweight.

THE 23° EYEWEAR COLLECTION IS BORN BASED ON A CIRCULAR “ECO-CONCEPT”: GENERATE GLASSES THAT GENERATE OTHER GLASSES, ELIMINATING WASTE.

Life-to-life: frame regeneration

Following a conscious recycling idea, if you would like to change your 23° Eyewear you can select a new design and return your current one. All design components, including the frame, the lenses, the logo and the optical screw, will be regenerated through a process of recycling or upcycling in order to create a new 23° item. If you decide to return your glasses to us, you will receive a 20% discount on the purchase of your next pair of 23° Eyewear.